Steam traps have become the most famous and useful machinery nowadays. They are employed in steam systems to capture steam and enable the release of non-condensates and condensable gases from steam machinery with a minimum loss of live steam. Various kinds of steam trap are widely used in every power plant sector, and they are the most important piece of machinery for any steam system.

Based on their construction and functioning theories, steam traps can be divided into three major types. Each of them has unique benefits and serves varied functions. If you want to use various types of steam trap for your next project, you have to learn everything about various steam trap, otherwise you cannot employ the appropriate steam trap for a particular purpose. We are going to discuss different types of steam trap in this article so that you can know everything about them before using.

Learn Everything about Various Types of Steam Traps and Their Applications

Steam trap play the most crucial role in every power plant sector. Therefore, steam trap have become an indispensable part of power plant sectors.

Mainly three types of steam trap are available in the market such as thermodynamic, mechanical and thermostatic steam trap. All types of steam traps offer numerous advantages and also they have several different applications that make them different from each other. Let us now tell you everything about different kinds of steam traps.

1. Thermodynamic Steam Trap

Thermodynamic steam traps are able to detect the velocities of entering fluids. This is one of the most common types of steam trap. These traps’ operating process is very much simple. Condensate discharge from the intake nozzle and it causes a pressure reduction as the speed rises. This will cause steam to flash, increasing the pressure needed to close a valve and lowering the trap’s condensate discharge rate.

Thermodynamic traps are advantageous in a number of ways. They are sturdy, reasonably priced, and tiny. These most advantageous steam traps are very simple to maintain because they only contain one moving part. They are unaffected by vibration or water hammer. These steam trap are ideal for high pressure high temperature steam.

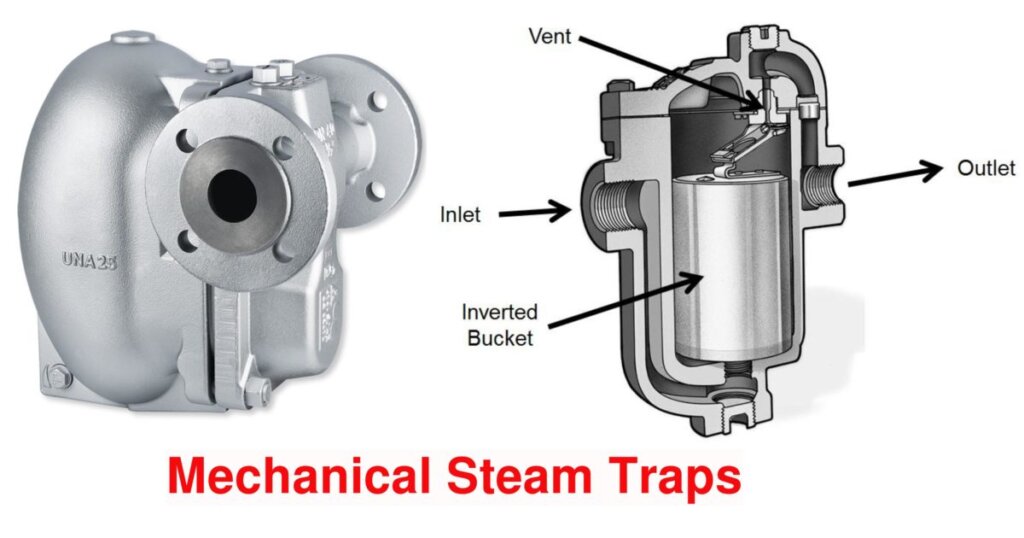

2. Mechanical Steam Traps

This one of the most useful steam trap among all types of steam traps. Mechanical steam trap are only open when a fluid is denser and closer when a fluid is less dense. Mechanical steam trap fall into two fundamental categories: float traps and inverted bucket traps. Inverted bucket traps use a cylindrical cup, while float traps use a spherical float.

With float steam trap, draining is possible continuously. On the other hand, because of their construction, inverted bucket traps only offer sporadic drainage. Mechanical steam trap are mostly employed in those steam systems that are used for secondary heating like coils, heat exchangers, vessels etc.

3. Thermostatic Steam Traps

These particular steam trap have the ability to detect the temperature difference between entering fluids. A component that comes from steam, drives the traps. It requires a temperature decrease for opening and releasing condensate. These traps are capable of working with the aid of filled or bimetallic elements.

Thermostatic traps are typically excellent at releasing huge amounts of air since air is much cooler than steam. Thermostatic traps have a range of 0 to 300 psig of operating pressure. These are the strongest steam traps among all kinds of steam traps due to their construction with stronger materials such cast iron housings, stainless steel, and carbon steel. For their extreme durability, these particular steam trap are widely used by various power plant industries in their steam machinery.

There are several uses of thermostatic steam trap. They are employed in high temperature tracing, and in some particular equipment that uses steam to remove condensate. Specially-filled balanced, Bi-metal, and expansion-type, all of these steam trapers can lower the temperature of the discharging temperature very smoothly by backing up and sub-cooling condensate. Therefore these steam trap are extremely useful for those situations when a particular item has to be stayed in a lower temperature than the temperature of steam.

Get the Right Kind of Steam Trap for Your Applications from ACME Fluid Systems

We hope that this information about various types of steam traps are enough for you. Each steam traps is very much beneficial and they are appropriate for a variety of uses. This blog will assist you in choosing the right steam traps for your needs. You can contact ACME Fluid Systems for more details on choosing the most appropriate steam trap for your applications.

One of the most famous and experienced steam trap manufacturers in India is ACME Fluid Systems. Our skilled team members make the strongest and most efficient steam traps for steam machines. We provide different varieties of steam traps for numerous applications in power plant industries. You can easily obtain the most appropriate steam trap for your applications from us at cheaper costs.